Mike discovered his life-long passion for the bicycle in 1964, when, at the tender age of seven, he began learning how to overhaul and repair bicycles from his father. M. Hartley Cycles (now known as ‘Mike’s Bikes’) was started in 1971, offering general bicycle repairs. In those years, in Toronto, Mike was riding the wave of the renewed interest in the bicycle as a means of transportation and recreation. Mike’s Bikes developed quickly, to building frames and wheels, engineering and designing frame components such as lugs, making complete bicycles, repairing and repainting frames, designing tools, and the importing of bicycle components.

Mike built his first frame when he was fifteen, using Prugnat lugs, Campagnolo forkends and Reynolds ‘531’ double-butted steel tubing.

One specialty of Mike’s Bikes, that developed early, is to design and build bicycles to accomplish unique requirements of the customer. The unique requirement of the bicycle shown below is ergonomical, and it was designed and built to allow shorter adults to ride a bicycle with two, equal-sized 700C wheels. The customer’s unique height was accommodated utilizing a sloping top tube, an extra-short head tube, a custom-engineered and hand-made head tube lug, and integrated top and down tubes.

Mike painted this innovative frame using a gravity-fed spray gun (a ‘first’ at that time in Toronto), made by ‘Aerospray Engineering, of Birmingham, England, and ideal for painting beautiful finishes on bicycle frames. In Toronto in the early ‘seventies, these kinds of guns were virtually unknown and unobtainable through the local supply chain. It had to be sourced overseas (there was no internet in the nineteen-seventies!). A small detail perhaps, but another indication of the lengths to which we will go, to step outside the usual to engineer, design, and manufacture innovative bicycles, tools, and services for commuters, couriers, cargo delivery, and touring.

Decades before the ‘built-where-it’s-sold’ movement became fashionable and topical, MIKE’S BIKES utilized local manufacturers to transform designs prepared in-house into finished products, beginning with our first engineered tool: a shop bicycle stand (still being used, forty-eight years later!).

Today, Mike’s Bikes engineers and designs bicycles for commuting, delivering cargo and parcels, and touring. Recently, we completed the research, engineering, and design of an internally geared, three-speed transmission in the bottom-bracket shell, to replace the derailleur. It also replaces the chain with a timing-belt drive, eliminating the need for lubrication, for all-weather, maintenance-free performance. The assembly drawing for this innovative bicycle, shown below, is prominently featured in our web-site. More recent improvements in the design incorporate the latest designs for internally-geared transmissions from around the world.

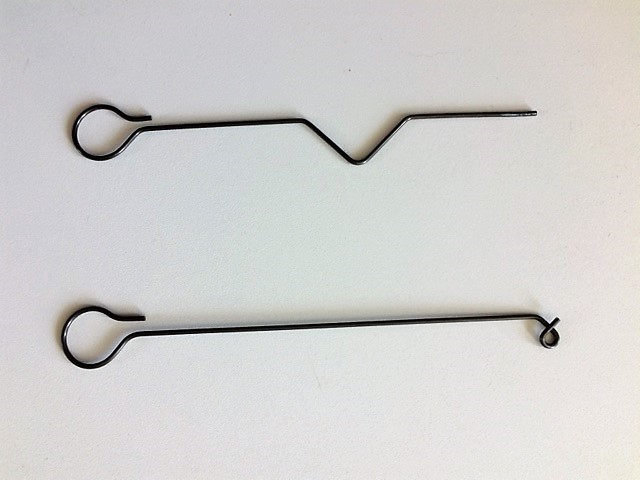

Our latest development is a set of spoke tools for the mechanic! Based on decades of shop experience repairing and building wheels, we have invented and engineered two tools that make it easier for the mechanic to replace spoke nipples, lubricate spoke threads, and to build bicycle wheels.

The demonstration video in ‘Products and Services’ shows how these tools will assist the mechanic to transfer spoke nipples and lubricate spoke threads more easily, in less time, every time, and without costly mistakes. Being manufactured locally (in Mississauga!), the sale of these tools also supports the local economy.

Mike’s Bikes also repairs and overhauls existing wheels and as well designs and hand-builds complete wheels for improved performance, durability, and reliability. These services, available on-line, are described in more detail in the ‘Products and Services’ of this web-site.